Product details PGT series metal disk vacuum filter fully absorb the advantages of similar foreign products, for large metal mineral density and fast subsidence, including the characteristics of the solids in the filtrate tube impact is strong, has carried on the overall performance and between various components reliability optimization design, to guarantee the metal material in the solid-liquid separation of fine dehydration. Its main technical indexes and performance have reached the level of domestic and foreign products. Main features: 1, the fan filter plate dewatering hole distribution is uniform, the pore rate is reasonable, the bar size is large, made of high strength engineering plastic, the service life is increased 1-1.5 times. 2, filtrate pipe filtration area, distribution head abdominal cavity area is large, improve the extraction rate and filtrate discharge effect. 3, wear-resistant nylon monofilament or double-layer multifilament filter cloth to increase the dehydration rate and not easy to plug, prolong the service life. 4, multi point dry oil pump concentrated automatic lubrication. 5, press cloth automatic cleaning device, maintain its good dehydration effect. 6, horizontal forced speed mixing, the shaft end adopts rubber and graphite packing and hydraulic pressure difference triple seal, to ensure no leakage of slurry. 7, the main drive continuously variable speed, according to the concentration and flow of the material regulation (AC speed motor or frequency converter), in order to achieve the ideal working effect. 8. Each plate is composed of 20 filter fan plates, which strengthens the control of the filtration process and makes the cake thick and uniform. 9. The friction plate is made of boron cast iron, which is a special wear-resistant material. It has good sealing effect and long service life. 10, filtrate pipe for high strength wear resistant ceramic composite steel pipe, improve the life of more than 10 times. 11. The upper and lower flanges are removed from the interface between the filtrate pipe and the filter fan, and the mold is used for direct welding to reduce the possible air leakage point by 90%

Product details

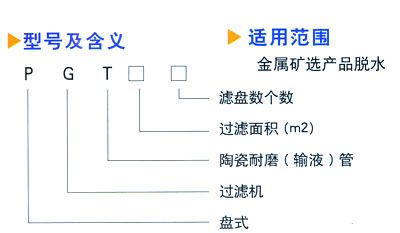

PGT series metal disk vacuum filter fully absorb the advantages of similar foreign products, for large metal mineral density and fast subsidence, including the characteristics of the solids in the filtrate tube impact is strong, has carried on the overall performance and between various components reliability optimization design, to guarantee the metal material in the solid-liquid separation of fine dehydration. Its main technical indexes and performance have reached the level of domestic and foreign products.

Main features:

1, the fan filter plate dewatering hole distribution is uniform, the pore rate is reasonable, the bar size is large, made of high strength engineering plastic, the service life is increased 1-1.5 times.

2, filtrate pipe filtration area, distribution head abdominal cavity area is large, improve the extraction rate and filtrate discharge effect.

3, wear-resistant nylon monofilament or double-layer multifilament filter cloth to increase the dehydration rate and not easy to plug, prolong the service life.

4, multi point dry oil pump concentrated automatic lubrication.

5, press cloth automatic cleaning device, maintain its good dehydration effect.

6, horizontal forced speed mixing, the shaft end adopts rubber and graphite packing and hydraulic pressure difference triple seal, to ensure no leakage of slurry.

7, the main drive continuously variable speed, according to the concentration and flow of the material regulation (AC speed motor or frequency converter), in order to achieve the ideal working effect.

8. Each plate is composed of 20 filter fan plates, which strengthens the control of the filtration process and makes the cake thick and uniform.

9. The friction plate is made of boron cast iron, which is a special wear-resistant material. It has good sealing effect and long service life.

10, filtrate pipe for high strength wear resistant ceramic composite steel pipe, improve the life of more than 10 times.

11. The upper and lower flanges are removed from the interface between the filtrate pipe and the filter fan, and the mold is used for direct welding to reduce the possible air leakage point by 90%

Technical parameters